The Essential Role of Solar Accessories in Energy Systems

Overview of Solar Accessories in Modern Energy Solutions

Solar accessories are pivotal components that enhance the efficiency and functionality of modern energy systems. They include various devices integral to the robust operation of solar panel installations, such as inverters, batteries, and charge controllers. These accessories not only aid in optimizing the performance of solar systems but also significantly impact their reliability and longevity. Numerous energy organizations emphasize their role in increasing energy efficiency and reducing operational costs, thus promoting sustainable energy solutions. By catering to both residential and commercial needs, these accessories ensure seamless power delivery and contribute to a greener future.

Balancing Efficiency with Safety and Durability

In solar energy systems, achieving a balance between efficiency, safety, and durability is crucial for optimal performance. Ensuring that solar installations are equipped with efficient and safe components prevents system failures and costly downtimes. This requires regular assessment of safety features, which are essential to user safety and the overall integrity of the system. Durability is vital as solar systems often encounter harsh environmental conditions—using high-efficiency products crafted from durable materials extends their lifecycle. Industry standards from leading solar authorities guide the selection of accessories that meet stringent efficiency, safety, and durability benchmarks, thereby supporting long-term energy solutions.

Critical Types of Solar Accessories for System Optimization

Solar Fuses and Circuit Breakers: Overload Protection

Solar fuses and circuit breakers are critical components in preventing equipment damage due to overload. They serve as the first line of defense against overcurrent and potential fire hazards. This essential role is underscored by research from reliability analysis, which shows that systems equipped with proper fusing are significantly less likely to suffer from electrical failures. This makes solar fuses and circuit breakers indispensable in any solar setup, reinforcing their necessity for maintaining system integrity and functionality.

Surge Protectors: Defending Against Voltage Spikes

Surge protectors play a crucial role in shielding solar installations from voltage spikes, which can be caused by lightning strikes and grid fluctuations. Such spikes have the potential to damage sensitive equipment, making surge protection vital. Statistics indicate that there is a marked improvement in system longevity when surge protection is in place. This underlines the protectors' importance in risk mitigation, ensuring the extended life and reliability of solar energy systems.

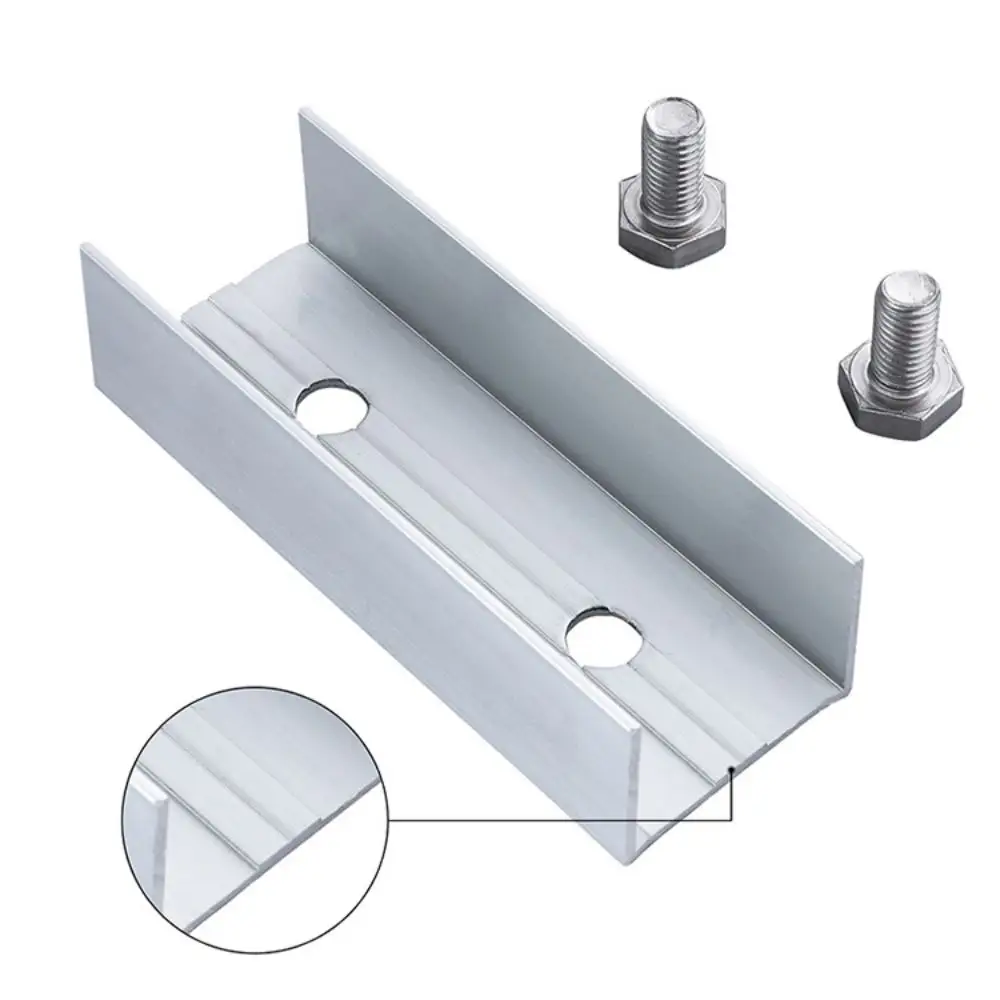

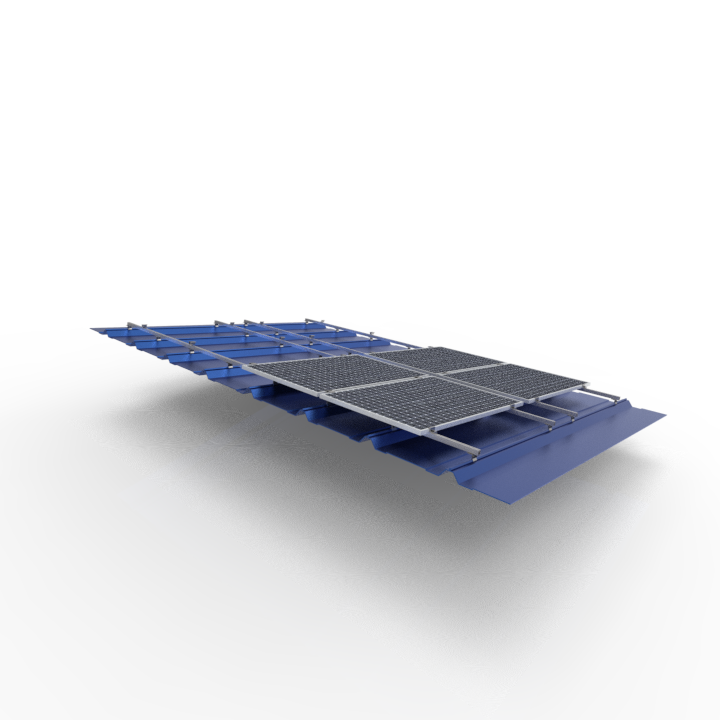

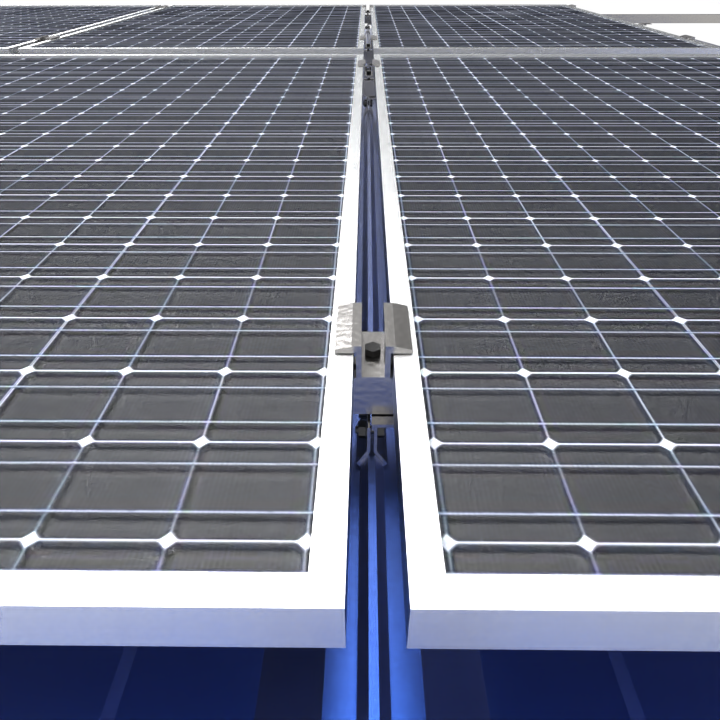

Robust Mounting Systems for Structural Stability

Robust mounting systems are vital for maintaining the structural stability of solar panels, especially in regions prone to high winds or heavy snow. In such environments, improper support can lead to catastrophic failures. Understanding and adhering to local building codes and best practices in mount selection not only optimizes performance but also assures compliance with safety regulations. This balance between form and function is essential for maximizing the efficiency of solar installations.

High-Quality Wiring and Conduits for Safe Energy Transfer

Quality wiring and conduits are crucial for the safe and efficient transfer of energy between solar components. This reduces energy losses significantly and minimizes potential hazards. Evidence from electrical safety studies confirms that using proper gauge wires enhances the overall performance of the solar system. By ensuring that wiring and conduits are of high-quality and correctly installed, solar energy systems can achieve optimal efficiency and safety, supporting both residential and commercial installations.

Enhancing Safety Through Advanced Solar Components

Preventing Electrical Fires with Proper Insulation

Proper insulation is essential to prevent electrical fires in solar installations, as they are a significant risk factor. The choice of high-quality insulation materials affects both the safety and reliability of a solar system. According to reports on insurance claims, poorly insulated systems frequently face higher risks of fire incidents. Therefore, adhering to recommended insulation standards is critical for safeguarding solar systems against potential fire hazards. By prioritizing proper insulation, solar installations can function more safely and efficiently, ensuring sustained energy production.

Grounding Systems for Hazard Mitigation

Grounding systems serve as a critical component in solar safety, playing a vital role in preventing electrical shocks and ensuring the entire system is properly earthed. Systematic data reveal that installations equipped with robust grounding systems experience considerably fewer electrical anomalies, demonstrating their importance in solar setups. Proper grounding effectively mitigates hazards by dissipating excess electrical charge, protecting both the equipment and users. As part of comprehensive safety measures, investing in a quality grounding system is indispensable for all solar installations.

Role of Monitoring Tools in Risk Detection

Monitoring tools are indispensable for risk detection in solar systems, allowing real-time assessment of system performance and the immediate identification of anomalies. Research has shown that systems utilizing monitoring tools can preemptively identify issues, substantially improving safety and operational efficiency. By enabling proactive maintenance and timely interventions, these tools are crucial for safeguarding against potential system failures. Integrating monitoring solutions into solar installations not only heightens overall safety but also enhances system longevity and reliability.

Improving Durability Against Environmental Stressors

Weather-Resistant Materials for Longevity

Utilizing weather-resistant materials in solar components dramatically increases their durability against environmental stressors, contributing to their long-term performance. These materials are crucial in areas experiencing extreme weather conditions, as they protect solar systems from elements like hail and storms. By sourcing materials with high resistance ratings, businesses can significantly reduce replacement frequency and maintenance costs, ensuring a more reliable and cost-effective investment.

Corrosion Protection in Solar Mounts and Frames

Corrosion protection is vital, especially for mounts and frames exposed to moisture and salts, as corrosion can severely limit operational lifespan. Studies have shown that solar systems equipped with effective anti-corrosion measures demonstrate improved resilience and require less maintenance, thereby extending their functional lifespan. Incorporating premium anti-corrosion coatings and materials helps in shielding these critical components from the harsh effects of environmental exposure.

Impact of Proper Installation on Component Lifespan

Proper installation techniques directly impact the lifespan of solar components, as incorrect setups can lead to premature failures and costly repairs. It is recommended to engage certified installation professionals who adhere to best practices and manufacturer specifications to ensure system longevity and efficiency. This not only minimizes maintenance requirements but also optimizes the performance of the solar system, safeguarding against unnecessary breakdowns and operational disruptions.

Maintenance Best Practices for Sustained Performance

Regular Inspections for Wear and Tear

Regular inspections are essential for detecting wear and tear, thereby preventing unexpected failures that can interrupt energy production. Solar panels and related accessories are constantly exposed to environmental factors that can degrade their quality over time. Industry best practices recommend bi-annual inspections to keep systems running at peak performance. These inspections help identify minor issues before they escalate, reducing repair costs and avoiding potential disruptions in energy output.

Cleaning Protocols to Prevent Efficiency Loss

Implementing regular cleaning protocols is vital to prevent dirt and debris accumulation, which can significantly hinder energy output. Dust, grime, and organic materials on solar panels can obstruct sunlight, reducing their efficiency. Data from solar performance studies suggests that cleaner panels can boost efficiency by up to 25%. A systematic cleaning routine ensures that panels operate at their full potential, contributing to consistent energy generation throughout the year.

Upgrading Outdated Components Proactively

Proactively upgrading outdated components is crucial for maintaining system efficiency and ensuring that all parts are functioning optimally. Older system components may struggle to keep up with new technological advancements, resulting in inefficiencies. Stakeholder surveys indicate that regular updates to technology reduce operational costs and enhance system reliability. By staying ahead with technology, system owners can leverage enhanced capabilities and ensure their investment continues to deliver maximum returns.

FAQ

What are solar accessories?

Solar accessories refer to the components used in solar energy systems, such as inverters, batteries, and charge controllers, which optimize the system's efficiency and longevity.

Why are safety and durability important in solar systems?

Safety and durability are critical to prevent system failures, reduce downtimes, and optimize long-term performance, especially under harsh environmental conditions.

How often should solar systems be inspected?

It is recommended to perform bi-annual inspections to detect any wear and tear and ensure optimal performance of the solar system.

Why is surge protection necessary for solar systems?

Surge protection is necessary to protect solar installations from damaging voltage spikes caused by factors like lightning or grid fluctuations.