Introduction: Importance of Choosing the Right Solar Roof Mounting System

In this expanding era of renewable energy, selecting the proper solar roof mounting system is pivotal for optimizing solar installations. It guarantees that solar panels are not only positioned effectively for maximum sun exposure but also ensures the longevity and efficiency of the roofing system itself. Understanding its crucial role, homeowners and businesses alike are increasingly focusing on choosing the optimal mounting solution.

Key role in energy efficiency and roof longevity

The correct solar roof mounting system plays a significant role in maximizing energy production by ensuring solar panels are ideally positioned for optimal sun exposure. Appropriate mounting systems contribute to roof longevity by distributing the weight evenly, reducing stress on roofing materials, and preventing potential damage over time. Industry studies underscore that efficient mounting systems can enhance energy efficiency substantially, ensuring a robust setup that potentially extends the lifespan of both the solar panels and roof. Robust mounting solutions ensure that your investment in solar energy pays off long-term by bolstering the durability of your panels and roof.

Impact on long-term savings and environmental benefits

An effective solar installation can lead to significant financial savings due to reduced energy bills, proving the long-term impact of a proper solar roof mounting system. Additionally, it offers substantial environmental benefits by enhancing solar energy harvesting, which in turn reduces carbon footprints. Studies have shown that homes equipped with efficient solar installations can experience notable savings and an impressive return on investment (ROI) over time. Expert opinions highlight that proper mounting systems are indispensable for enhancing the sustainability of residential energy solutions, paving the way for a greener future while safeguarding financial interests. By choosing the right solar roof mounting system, you not only ensure energy efficiency but also contribute positively to the environment and long-term savings.

Roof Type and Structural Compatibility

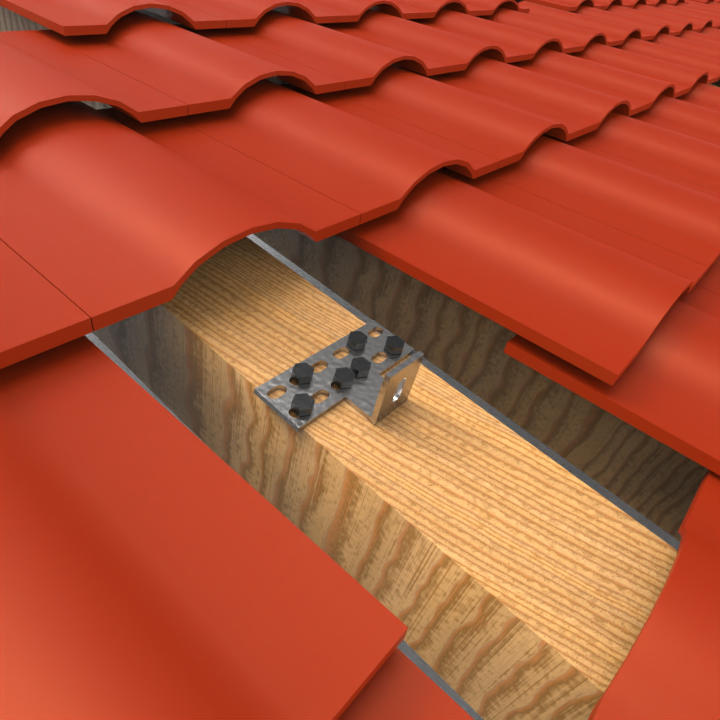

Evaluating Roof Materials (Asphalt, Tile, Metal, Flat Roofs)

Choosing the right solar roof mounting system begins with understanding the different roof materials as each requires a specific installation approach. Asphalt shingles, being the most common material, are easy to penetrate but require careful sealing to avoid leaks. Tile roofing requires mounting systems designed to avoid cracking tiles during installation. Metal roofs use clamps rather than penetrations, which is advantageous for maintaining roof integrity. Flat roofs often employ ballasted mounts that do not require drilling, thus protecting the roof membrane. Each material’s unique characteristics determine the appropriate solar roof mounting system ensuring efficient energy capture without compromising roofing integrity.

Assessing Load-Bearing Capacity and Structural Integrity

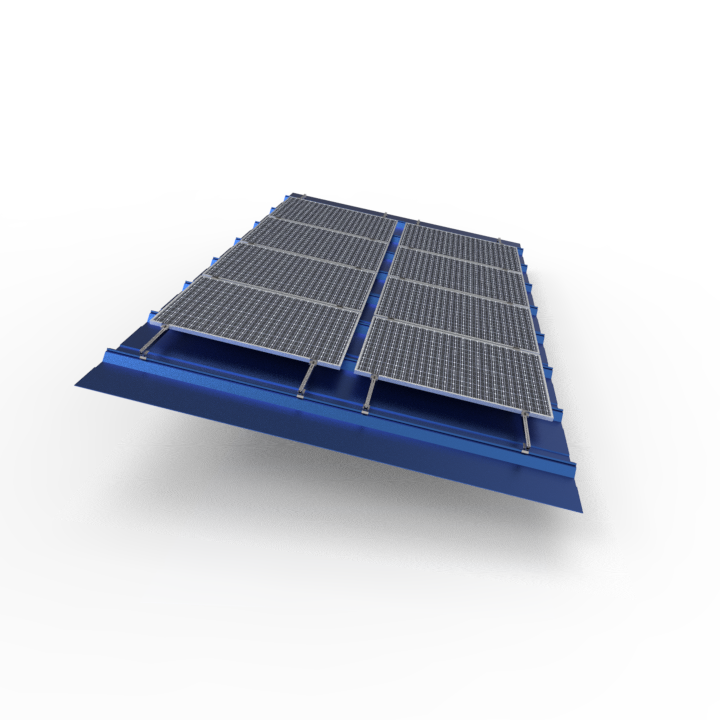

Before installing solar panels, it's crucial to assess the load-bearing capacity and structural integrity of the roof. Solar roof mounting systems introduce additional weight, and improper assessment may lead to structural failure. The recommendations of structural engineers should be sought for insights into safe load limits. For instance, flat roofs might require reinforcement to safely support panel weight and withstand environmental loads like snow or wind. Ensuring the roof’s integrity not only supports the mounting system securely but also prolongs the lifespan of both the roofing and the solar installation itself.

Mounting System Durability and Weather Resistance

Material Choices: Aluminum vs. Stainless Steel

Choosing the right material for solar mounting systems is essential for durability and efficiency. Aluminum and stainless steel are the two primary materials used, each with its advantages. Aluminum is lightweight and cost-effective, which makes it an economical choice for many installations. However, it may not offer the same level of durability as stainless steel in harsh weather conditions. On the other hand, stainless steel boasts superior corrosion resistance and longevity, making it ideal for areas prone to extreme weather. While more expensive, its robustness can justify the cost in the long run. Experts suggest that material selection should also consider local climate, advising stainless steel for coastal or high-humidity areas to prevent corrosion.

Resistance to Wind, Snow, and Seismic Factors

Designing solar mounting systems to withstand environmental pressures is crucial for safety and longevity. Systems must cope with extreme weather conditions such as high wind speeds and heavy snow loads. For instance, solar installations can face wind speeds above 110 miles per hour and snow loads exceeding 30 pounds per square foot in some regions. Additionally, seismic considerations are vital in earthquake-prone areas. Adhering to local building codes and standards helps ensure structural resistance and safeguards investments. The International Building Code (IBC) provides guidelines that emphasize these aspects, ensuring installations remain secure under various environmental stressors.

Installation Process and Maintenance Requirements

Ballasted vs. Penetrating Mounting Systems

When considering solar panel installations, understanding the difference between ballasted and penetrating mounting systems is crucial. Ballasted mounting systems hold panels in place using weights, making them ideal for flat or slightly sloped roofs where penetration is undesirable. They are particularly useful in commercial settings where roof integrity must remain intact. Conversely, penetrating mounting systems require drilling into the roof to secure mounts with bolts or screws, offering a more permanent solution suitable for various roof types that can support such installations. Each method has its advantages and disadvantages; ballasted systems are easier to install but may be limited by weight constraints, while penetrating systems provide stronger holds but can affect roof integrity. Selecting the right system involves considering roof type, environmental factors, and local regulations to ensure compliance and optimal performance.

Professional Installer Qualifications and Certifications

Securing qualified and certified installers is paramount to ensuring the successful implementation of solar roof mounting systems. Professional credentials, such as the North American Board of Certified Energy Practitioners (NABCEP) certification, play a significant role in demonstrating expertise and installation quality. NABCEP-certified installers adhere to industry standards, which reduces the risk of system failure and enhances long-term performance. Homeowners have shared positive experiences, highlighting how skilled professionals have completed installations efficiently and experts have resolved unforeseen challenges effectively. Certified installers not only offer peace of mind but also contribute to maximizing the return on solar investments through meticulous craftsmanship.

Aesthetic Impact on Home Design

Minimizing visual disruption with low-profile designs

Low-profile solar mounting systems are rapidly gaining popularity due to their ability to harmonize with various architectural styles while minimizing visual disruption. These systems are designed to sit closer to the roof, offering a sleeker appearance compared to traditional mounts. For example, some low-profile designs blend seamlessly with both traditional and modern homes, maintaining aesthetic charm without compromising energy efficiency. Not only do they offer aesthetic advantages, but they also provide functional benefits such as enhanced wind resistance, ensuring stability and durability in various weather conditions.

Color-matching and architectural integration

Color-matching between solar panels and mounting systems significantly enhances the curb appeal of homes. By choosing modules that align with the color palette of the roof, homeowners can ensure that their solar installations do not stand out against the style of the house. Experts have highlighted the importance of architectural integration, suggesting that it maintains the unified design language of the home. Modern design trends are increasingly favoring solar installations that complement the existing architecture, resulting in both an eco-friendly and visually appealing enhancement to properties.

Balancing functionality with curb appeal

To achieve the perfect blend of functionality and curb appeal in solar roof mounting systems, homeowners should strive for installations that fulfill both energy and aesthetic goals. Selecting the right system involves considering factors such as the roof's angle, color scheme, and overall architectural style. By doing so, they can ensure that solar panels not only meet energy needs but also enhance the property's value. Case studies reveal that successfully integrated solar systems can significantly boost home value, demonstrating that it is possible to balance energy performance with captivating design elements.

Warranty and Support

A comprehensive warranty plays a pivotal role in the decision-making process for solar roof mounting systems. It provides assurance on the product's durability, performance, and the quality of installation. Customers should look for warranties that cover different aspects such as the product itself, the energy performance over time, and labor warranties, which ensure coverage for installation or repair-related issues. These warranties not only safeguard against potential defects but also contribute significantly to the overall value and reliability of the solar investment.

Solid customer support from the manufacturer is equally crucial. Numerous customer reviews highlight how responsive and competent customer support teams can notably influence long-term satisfaction with solar mounting systems. Effective customer support not only helps in resolving technical issues swiftly but also provides guidance throughout the installation and maintenance process. This ensures that any concerns are addressed promptly, thereby enhancing customer experience and trust in the product quality. Hence, strong warranties paired with reliable customer support build confidence in purchasing decisions and are essential for ensuring long-term value.

FAQs

Why is choosing the right solar roof mounting system important?

Choosing the correct solar roof mounting system is vital for maximizing solar panel efficiency, ensuring roof longevity, and providing long-term financial and environmental benefits.

What should be considered regarding roof materials for solar installation?

Each roof material, such as asphalt, tile, or metal, has unique characteristics requiring specific installation approaches to ensure effective solar energy capture and roof integrity.

How do I ensure my solar installation can handle environmental conditions?

Select materials like stainless steel for enhanced weather resistance, adhere to local codes, and ensure the system is designed to withstand wind, snow, and seismic factors.

What are the benefits of using low-profile solar mounting systems?

Low-profile designs minimize visual disruption and improve curb appeal, aligning with architectural styles and often providing better wind resistance.