How do I choose the right solar panel mount for my specific needs and location?

Installing solar panels is a significant step, but have you considered how to mount them? It's essential to choose the right solar panel mount, as it can greatly impact energy efficiency and durability. Factors such as your roof type, available space, and energy goals all contribute to this decision. Let’s explore what works best for you.

Types of Solar Panel Mounts

When it comes to solar panel mounts, you’ve got three main options. Each type has its own benefits and works best in specific situations. Let’s break them down so you can decide what fits your needs.

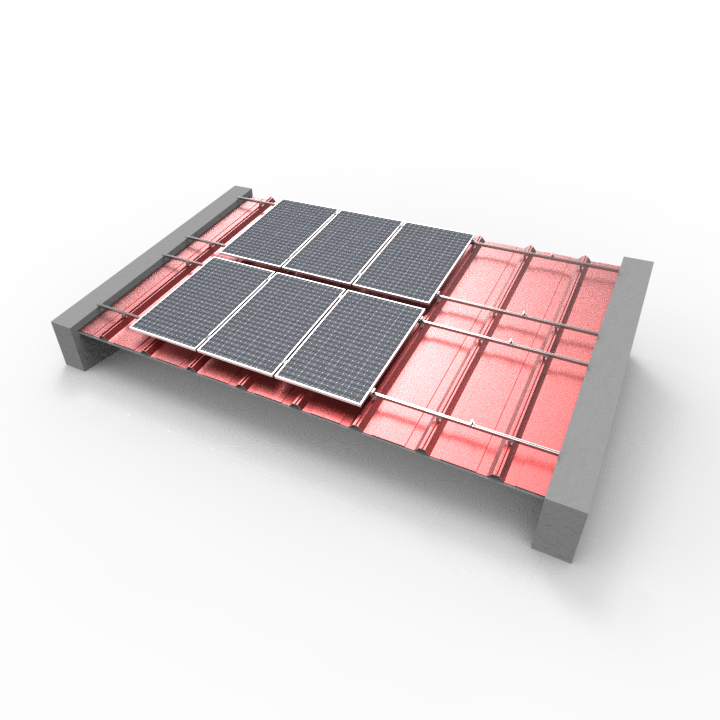

Roof-Mounted Systems

Roof-mounted systems are the most common choice for residential solar panels. These mounts attach directly to your roof, making them a space-saving option. If your roof gets plenty of sunlight and is in good condition, this might be the perfect fit. They work well for sloped or flat roofs, though the installation process can vary.

One thing to keep in mind is accessibility. Once installed, roof-mounted panels can be harder to clean or repair. But if you want to maximize your roof’s potential and save ground space, this system is worth considering.

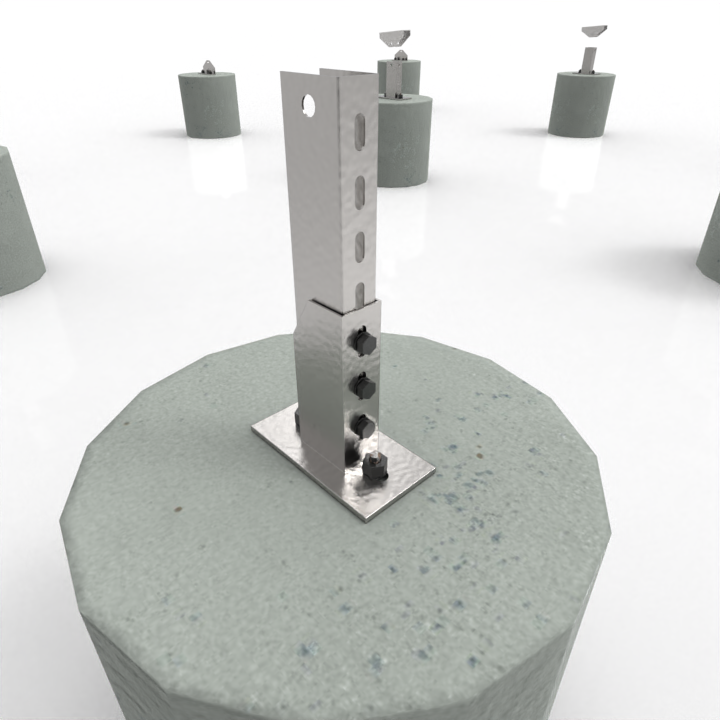

Ground-Mounted Systems

If you’ve got extra yard space, ground-mounted systems could be a great option. These mounts sit on the ground, giving you more flexibility with placement. You can position them to capture the most sunlight, even if your roof isn’t ideal for solar panels.

Ground-mounted systems are also easier to maintain since they’re at ground level. However, they do take up space, so you’ll need to evaluate your property’s layout before committing.

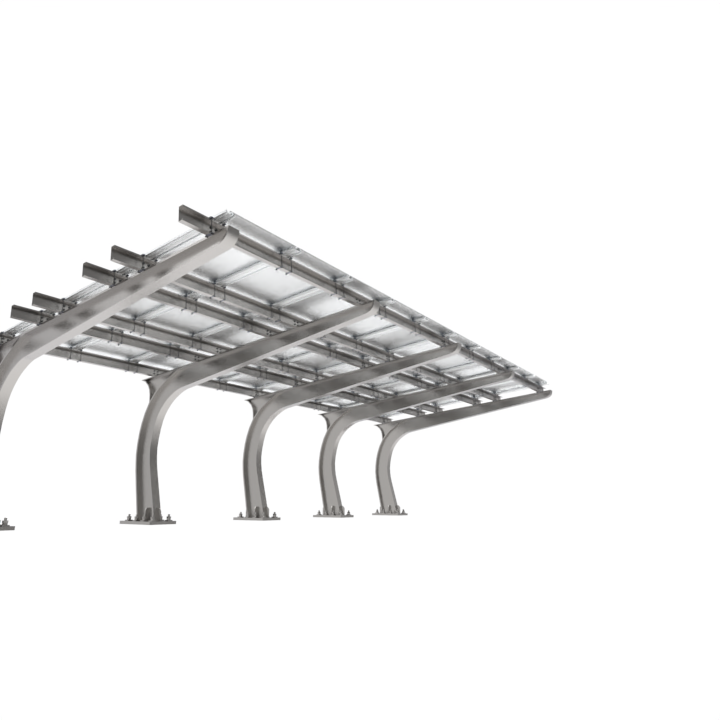

Tracking Systems

Tracking systems are the high-tech option. These mounts follow the sun’s movement throughout the day, ensuring your panels get maximum exposure. They’re perfect if you want to boost energy production and have the budget for advanced technology.

While tracking systems can generate more power, they’re also more expensive and require regular maintenance. If you’re aiming for efficiency and don’t mind the extra cost, this could be the right choice for you.

How to Choose the Right Solar Panel Mount for Your Needs

Evaluating Roof Type and Condition

Your roof plays a big role in deciding which solar panel mount works best. Start by checking its condition. Is it sturdy enough to handle the weight of solar panels? If your roof is older or needs repairs, you might want to fix it first. The type of roof you have also matters. For example, sloped roofs often work well with fixed mounts, while flat roofs may need tilted systems to catch more sunlight.

Think about the material too. Asphalt shingles, metal, or tile roofs all require different mounting techniques. If you’re unsure, a professional installer can help you figure out what’s compatible. By evaluating your roof, you’ll be one step closer to choosing the right solar panel mount.

Assessing Ground Space Availability

If your roof isn’t ideal, take a look at your yard. Do you have enough open space for a ground-mounted system? These mounts need a flat or slightly sloped area with minimal shading. Trees, fences, or buildings can block sunlight and reduce efficiency.

Ground-mounted systems give you flexibility. You can position them to face the sun directly, which boosts energy production. However, they do take up space, so make sure you’re okay with sacrificing some yard area. If you’ve got the room, this option could be a game-changer.

Aligning with Energy Goals and Budget

What are your energy goals? Are you looking to power your entire home or just reduce your electricity bill? Your answer will guide your choice. Tracking systems, for instance, maximize energy output but come with a higher price tag. Fixed mounts are more budget-friendly but might not capture as much sunlight.

Set a budget before you decide. Remember, the cheapest option isn’t always the best. Think long-term. A system that costs more upfront might save you money in the future. By aligning your goals and budget, you’ll make a smarter choice when you choose the right solar panel mount.

Choosing the right solar panel mount doesn’t have to feel overwhelming. You just need to understand the types of mounts, evaluate your needs, and think about your location. By doing this, you’ll set yourself up for an efficient and durable solar system. Need help? Consult a professional or try online tools to get started!