Understanding Solar Inverter Types and Applications

String Inverters: Cost-Effective Solutions for Optimal Sunlight

String inverters are among the most widely used inverter types, especially in residential solar systems, providing a cost-effective solution for homeowners who enjoy optimal sunlight conditions. These inverters convert direct current (DC) generated by solar panels into alternating current (AC), which is necessary for powering household appliances. Their effectiveness is maximized in situations where sunlight is abundant and shading is minimal, thus ensuring maximum efficiency and performance. String inverters are particularly suited for simpler and unshaded roof layouts, where solar panels can receive consistent sunlight throughout the day. By maintaining high efficiency in such conditions, string inverters prove to be an economical choice for many residential installations.

Microinverters: Maximizing Efficiency in Complex Roof Layouts

Microinverters offer a unique advantage by working with each solar panel individually, thereby enhancing energy harvest in installations with complex roof layouts. This feature is particularly beneficial in scenarios where shading occurs, as microinverters ensure that the performance of unshaded panels is not compromised. Installing microinverters can significantly improve overall system yield by maximizing energy output from each panel, regardless of its orientation or shading. Microinverters also provide precise monitoring capabilities, allowing homeowners to track the performance of individual panels and quickly identify issues for prompt resolution. These qualities make microinverters ideal for solar systems installed on roofs with varying angles, shading challenges, or unconventional designs.

Evaluating Efficiency Metrics and Performance

Peak vs. Weighted Efficiency: Key Differences

Understanding the differences between peak and weighted efficiency is critical when evaluating solar inverters. Peak efficiency refers to the maximum energy output an inverter can achieve under ideal conditions. While it offers a glimpse of potential performance, it often does not reflect daily operations where environmental factors like shading or temperature fluctuations are present. This contrasts with weighted efficiency, which considers real-world conditions. It accounts for variations in sunlight and temperature over time, making it a more reliable measure of actual performance. Homeowners selecting inverters should compare these efficiency metrics to determine the appropriate setup for their specific installation circumstances. This comparison ensures they get the best energy conversion rates tailored to their system’s unique conditions.

Impact of Shading and Temperature on Output

Shading is a significant factor in solar energy production, as it can greatly diminish the output of solar panels. This makes it crucial to understand how different inverters manage shading to maintain system performance. Additionally, high temperatures can negatively affect inverter performance, reducing both efficiency and longevity. The materials and technologies used in inverter production can mitigate these effects. Evaluating how inverters perform under varying environmental conditions is essential to ensure consistent, reliable performance throughout their lifespan. By choosing equipment that effectively manages shading and temperature fluctuations, users can optimize their energy systems, maintaining high levels of output and efficiency year-round.

Durability and Warranty Considerations

Weather Resistance for Harsh Climates

In regions with extreme weather conditions, selecting inverters with high weather resistance is crucial for maintaining the integrity and efficiency of solar energy systems. Look for inverters that come with certifications, such as IP (Ingress Protection) ratings, which indicate their ability to withstand environmental challenges like extreme temperatures, humidity, and storms. A well-rated inverter ensures minimal disruptions to energy conversion processes and reduces the likelihood of frequent maintenance, thereby safeguarding your investment in solar technology. By prioritizing durability, system longevity is enhanced, offering continuous energy supply even under severe climate conditions.

Interpreting Warranty Terms and Coverage

When investing in solar technology, understanding warranty terms and conditions is essential to ensure product reliability and confidence. Typically, longer warranty periods are indicative of the manufacturer's confidence in their product's durability and performance. It's important to examine what aspects the warranty covers—such as performance, parts, and labor—to fully comprehend the extent of protection offered. Reviewing customer testimonials and comparisons between different manufacturers can further illuminate the reliability and customer service standards. This informed approach will help users select a solar inverter with robust support, ensuring peace of mind and long-term satisfaction with the equipment.

Compatibility with Solar Panels and System Design

Matching Inverter Capacity to Panel Arrays

Choosing the correct inverter capacity is crucial for maximizing the efficiency of solar energy systems. Properly matching the inverter’s capacity with the power output of your solar panel arrays ensures optimal energy production. If your system is over-sized or under-sized, it can lead to inefficiencies that could impact overall performance and energy output. Factors such as the number of panels, their wattage, and expected energy generation rates should all be considered. By evaluating these elements, you can select an inverter that balances your system’s capacity with its energy production needs, ensuring effective and efficient operation.

Voltage Alignment for Seamless Integration

Voltage compatibility between solar panels and inverters is essential for efficient energy transfer and seamless integration. Ensuring that the inverter matches the voltage outputs of the panel array can help prevent potential equipment damage and ensure safe, effective operation. Consulting with an expert during the installation process can help avoid common pitfalls associated with voltage mismatches, such as energy loss or damage to system components. Seamless voltage alignment enhances the overall efficiency of the solar energy system, promoting a stable and reliable energy supply.

Monitoring Capabilities and Smart Features

Real-Time Performance Tracking Tools

Modern inverters are increasingly equipped with sophisticated monitoring tools that provide real-time data on energy production. These tools empower users to track their solar system's performance and make necessary adjustments to enhance efficiency. By examining the performance reports, homeowners can identify and address any inefficiencies, ensuring optimal energy generation. Additionally, the availability of mobile apps allows users to monitor their solar energy production remotely, adding convenience to their management processes. This capability is crucial for maximizing the benefit derived from solar systems and ensuring seamless operation.

Integration with Home Energy Management Systems

Smart inverters offer advanced compatibility with home energy management systems, facilitating better energy usage and heightened automation. Through this integration, homeowners can make informed decisions regarding their electricity consumption, ultimately reducing costs. By managing their solar energy system alongside other energy-dependent devices, users can significantly improve overall household efficiency. This interoperability not only enhances the user's ability to track and control energy usage but also contributes to optimizing power distribution across various appliances. Employing a smart inverter system represents a forward-thinking approach to energy management, offering both economic and operational benefits.

Balancing Budget and Long-Term Value

Upfront Costs vs. Lifetime Energy Savings

When considering solar technology investments, upfront costs can be daunting; however, opting for a high-quality inverter can significantly lower expenses in the long run. By reducing electricity bills, the initial investment may be offset over time. Calculating the payback period helps consumers determine how long it will take for energy savings to cover the inverter's cost, offering a clearer picture of long-term savings. It's also essential to consider maintenance costs alongside energy savings for a comprehensive understanding of the inverter's true lifetime value. This approach helps ensure that buyers make informed decisions that balance initial expenditure with sustainable savings.

Financing Options and Government Incentives

Exploring various financing options can help alleviate the initial burden of purchasing a solar system. Available federal and state incentives significantly reduce costs, making solar an attractive investment. For those considering a solar carport, for example, understanding and utilizing these incentives can make solar energy more accessible and affordable. Staying updated on new programs and grants offers opportunities to enhance financial efficiency. By maximizing these resources, consumers can enjoy the financial benefits of going solar without the stress of substantial upfront costs. Such strategic financial planning ultimately enhances the affordability and attractiveness of solar investments.

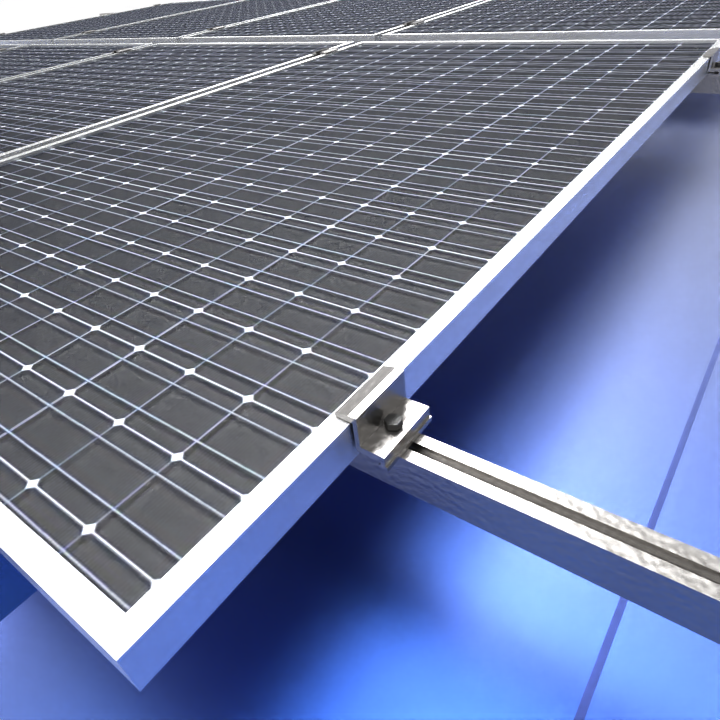

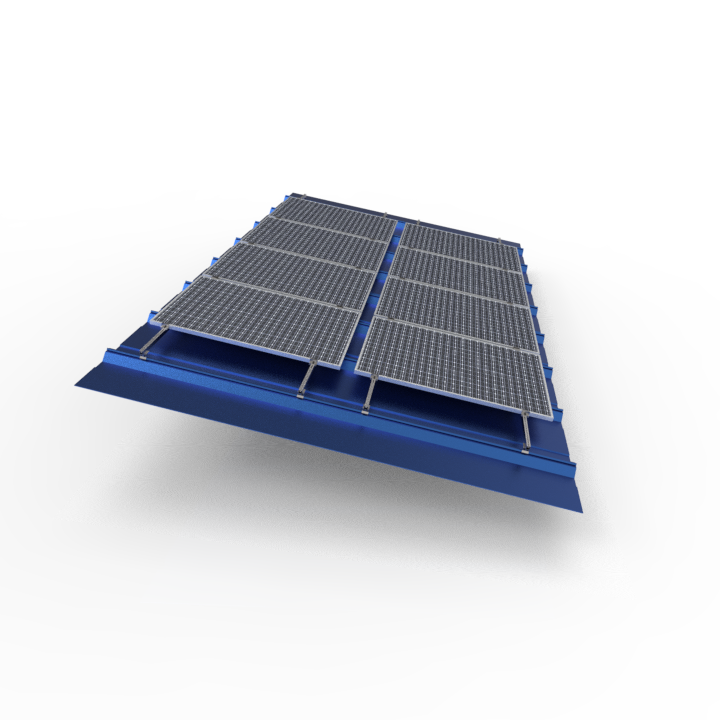

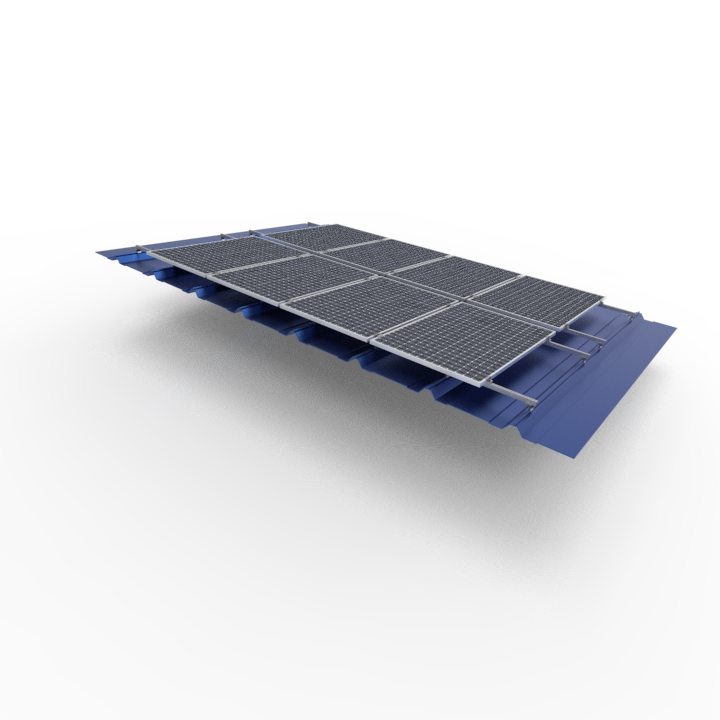

Installation Considerations for Mounting Systems

Roof vs. Ground Mounting: Space and Accessibility

When choosing between roof and ground mounting systems for solar panels, space and accessibility are primary considerations. Roof-mounted systems save valuable ground space and can be ideal for properties with limited land. However, depending on the design of the building, maintaining roof-mounted systems can be challenging, as accessibility might be restricted. On the other hand, ground mounts provide easier access for ongoing maintenance and often allow for the installation of a larger array, potentially yielding greater energy output. Nonetheless, they do require a significant amount of land, making them less feasible in urban environments.

Solar Carport Kits: Addressing Shading Challenges

Solar carport kits present an innovative solution to shading challenges, offering dual benefits: shelter and energy generation. These kits are particularly beneficial in urban settings, where rooftop space is limited, providing a practical alternative for solar installations. They allow property owners to utilize parking areas for solar energy generation, efficiently addressing space constraints. Moreover, evaluating the structural integrity and energy output of such carport solutions is essential to ensure they meet desired performance and safety standards. The ability to maximize urban areas for solar setups aligns with sustainable urban development goals, making solar carports increasingly popular.

FAQ

What are string inverters?

String inverters are cost-effective inverter types used in residential solar systems that convert DC generated by solar panels into AC for household appliances.

How do microinverters work?

Microinverters work with each solar panel individually, maximizing energy harvest and providing precise monitoring capabilities, especially in complex and shaded roof layouts.

What is peak efficiency?

Peak efficiency refers to the maximum energy output an inverter can achieve under ideal conditions, not necessarily reflecting daily operational conditions.

Why is weather resistance important for solar inverters?

Weather resistance is crucial to ensure the inverter withstands environmental challenges, maintaining system integrity and efficiency in harsh climates.

How can I optimize my solar panel system's efficiency?

Optimizing efficiency involves matching inverter capacity with panel arrays, ensuring voltage alignment, and using real-time tracking tools.