Introduction to Energy Storage Systems and Modern Innovations

The Growing Importance of Energy Storage in Renewable Integration

Energy storage systems (ESS) are pivotal in the transition to renewable energy resources like solar and wind. As governments and industries worldwide aim for a cleaner energy mix, ESS become critical infrastructure. These systems are essential in addressing grid stability and efficiency by storing energy when production exceeds demand and releasing it when needed. According to projections, the global market for ESS is set to skyrocket, potentially reaching $700 billion by 2027. This surge reflects the expanding investment in renewables. Energy storage ensures that intermittent energy sources can be effectively integrated into national grids, balancing supply and demand, and significantly reducing energy wastage. Therefore, they play a vital role in stabilizing energy grids and making them reliable even when solar or wind resources are scarce.

Key Challenges Addressed by Latest Innovations

Energy storage faces several challenges, including high costs, inefficiency, and scalability issues. Recent innovations in battery technology have aimed to tackle these problems head-on. Advances in battery chemistry and material sciences have yielded more efficient and durable batteries, enhancing energy storage performance. For example, recent data indicates that while initial deployments of ESS faced setbacks like fast degradation and high lifecycle costs, newer technologies now mitigate these issues more effectively. Scalability remains a focal point, with developments in manufacturing processes increasing production capabilities and driving down costs. Thus, these innovations are crucial in overcoming the barriers that previously hindered wide-scale deployment of energy storage solutions, making them more accessible and economically viable.

Solid-State Batteries: Revolutionizing Safety and Efficiency

How Solid-State Technology Enhances Energy Density

Solid-state batteries present a significant advancement over traditional lithium-ion models, primarily due to their utilization of solid electrolytes rather than liquid or gel. This fundamental distinction allows for a denser packing of energy, effectively increasing the energy density by up to 50%. This improved energy density translates directly to longer-lasting battery life in electric vehicles (EVs) and electronic devices, making them more efficient and reliable. According to recent studies, the market adoption rate for solid-state technology is predicted to increase substantially as manufacturers aim to meet the growing demand for high-performance batteries in various sectors. The shift towards solid-state batteries is expected to play a crucial role in the energy storage systems of the future, especially as renewable energy integration becomes more widespread.

Safety Advantages Over Traditional Lithium-Ion Batteries

Solid-state batteries offer substantial safety benefits, addressing the well-known risks associated with lithium-ion batteries, such as fires and thermal runaway. The solid electrolytes used in solid-state batteries reduce these risks significantly by eliminating flammable liquid components. Several expert analyses and case studies have demonstrated lower failure rates for solid-state batteries compared to their lithium-ion counterparts. Furthermore, industry guidelines and safety certifications have bolstered public confidence in solid-state technologies, defining them as a safer alternative. Such advancements in battery safety are crucial, especially in applications involving high energy demands like EVs and grid-scale energy storage systems.

Current Challenges and Future Commercialization

Despite their potential, solid-state batteries face technical and economic hurdles that impede widespread adoption. One of the primary challenges is the high manufacturing costs and the difficulty of scaling production to meet global demands. Some ongoing pilot projects and partnerships aim to address these issues, with some manufacturers targeting commercialization by 2025. The role of government policies and incentives is vital in facilitating the development and adoption of solid-state technologies. These initiatives can help mitigate market challenges and accelerate the transition to safer, more efficient battery solutions, aligning with global efforts to enhance renewable energy usage and storage capacities.

Flow Batteries: Scalable Solutions for Grid-Scale Storage

Mechanics of Redox Flow Battery Systems

Redox flow batteries are an innovative solution in energy storage mechanics, offering unique operational principles. These batteries store energy chemically by flowing liquid electrolytes across a membrane, allowing for controlled energy discharge when needed. Their standout feature is the ease of capacity scaling; adding more tanks of active materials increases storage capacity, making them highly adaptable for grid storage needs. Successful implementations in pilot projects across various regions highlight their effectiveness. For example, several projects around the world have demonstrated their utility in stabilizing electrical grids by storing large amounts of energy efficiently.

Applications in Long-Duration Renewable Energy Storage

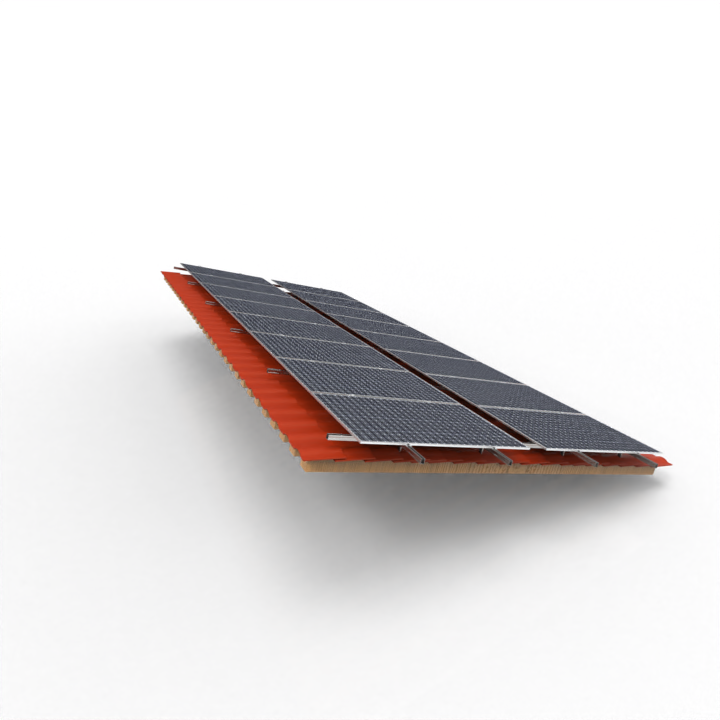

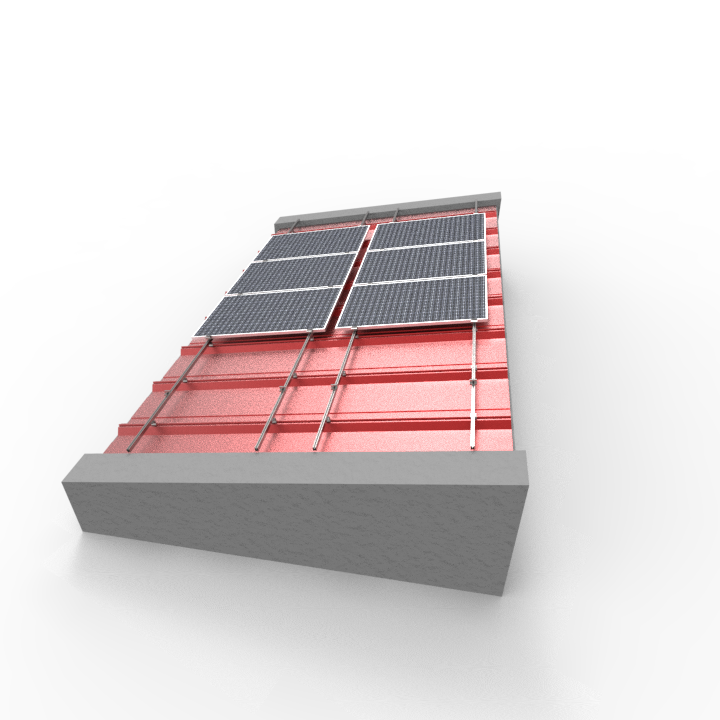

Flow batteries shine in scenarios demanding long-duration energy storage, particularly in renewable energy applications. They can adeptly balance the intermittent nature of renewable energy sources with ongoing energy needs, ensuring reliable power supply. Globally, flow batteries have been deployed in multiple renewable energy projects. A notable case study involves their usage in solar and wind farms, where they store surplus energy for use during periods of low generation. These applications underscore their potential to reshape future energy infrastructures by providing consistent and sustainable energy solutions, paving the way for more extensive renewable energy adoption.

Cost-Effectiveness and Environmental Benefits

Flow batteries offer cost-effectiveness and environmental benefits, positioning them as a preferable alternative to conventional energy storage technologies. Over their lifecycle, flow batteries tend to incur lower operational costs due to their flexible scalability and long service life. Environmentally, they are advantageous, as they have lower carbon emissions during manufacturing and operation compared to traditional batteries. Industry studies have cited significant cost savings and reduced environmental impact as incentives for early adopters, illustrating how flow batteries can contribute to both economic efficiency and ecological sustainability in energy storage systems.

In summary, flow batteries present scalable, economical, and environmentally friendly solutions for managing large-scale energy demands, particularly from renewable sources. Their ability to integrate seamlessly with existing energy infrastructures and support longer duration storage needs makes them a critical component in the transition towards sustainable energy systems.

AI-Powered Energy Storage Optimization

Machine Learning for Predictive Energy Management

Machine learning algorithms play a crucial role in optimizing energy demands by dynamically managing storage systems. These algorithms can analyze vast amounts of data to predict energy needs and adjust supply accordingly, leading to efficient energy distribution and minimized wastage. For instance, AI-enhanced systems have been successfully implemented in real-time energy management, showcasing significant improvements in operational efficiency and responsiveness. Emerging technologies continue to advance AI capabilities in energy solutions, promising further enhancements in predictive management and smart energy systems.

Case Studies: AI-Driven Grid Stabilization

Utilities worldwide are leveraging AI to stabilize and more effectively manage their grid systems. Specific examples include AI-driven solutions that have reduced energy losses, improved response times, and optimized grid performance. For instance, AI applications have demonstrated up to 15% reductions in energy losses and halved response times, showcasing the transformative potential of AI in grid management. Looking ahead, AI is expected to increasingly enhance energy storage systems, supporting larger-scale optimization efforts.

Enhancing Efficiency in Residential and Utility Systems

AI technologies are poised to revolutionize residential energy storage systems by optimizing energy consumption, reducing utility costs, and improving overall efficiency. Several products currently integrate AI to optimize these systems, providing quantitative improvements such as 20% lower energy bills and enhanced energy use efficiency. This evolution paves the way for future trends in AI that will integrate more deeply into both residential and large-scale utility energy systems, providing smarter, more autonomous energy solutions.

Hydrogen Storage: Bridging Clean Energy Gaps

Hydrogen as a promising solution for long-term energy storage and its environmental benefits

Hydrogen storage systems present a promising solution for surplus renewable energy storage, effectively bridging the gaps in clean energy. These systems can store energy generated during peak production times from sources such as wind and solar and release it during periods of high demand, thus ensuring a more consistent energy supply. The environmental benefits of using hydrogen as an energy carrier are substantial, with zero emissions at the point of use, making it an eco-friendly alternative to fossil fuels. Hydrogen's versatility and clean usage make it an excellent option for aiding in renewable energy integration.

1. Hydrogen Storage Systems for Renewable Energy: Hydrogen has the potential to capture excess electricity generated from renewable sources, store it efficiently, and then convert it back into electricity when needed, helping maintain grid stability.

2. Environmental Benefits: It offers cleaner energy storage solutions compared to conventional methods, as it releases no harmful emissions when used, contributing significantly to reducing the carbon footprint.

3. Current Projects Utilizing Hydrogen Storage: There are various initiatives worldwide focusing on hydrogen storage. For example, the Energy Earthshot initiative by the US Department of Energy aims to bring grid-scale hydrogen storage solutions into mainstream usage with significant funding level support.

By supporting intermittent renewable sources, hydrogen storage not only advances environmental sustainability but also tackles the challenge of long-term energy storage inherent in fluctuating renewable energy production.

Conclusion: Recap of the Latest Innovations and Their Potential to Revolutionize Energy Storage Systems.

The advancements in energy storage systems signal a transformative era for energy management. From hydrogen storage systems that bridge renewable energy gaps to zinc-based batteries offering longer storage durations and iron-air systems promising extended reliability, these innovations are set to redefine energy storage paradigms. Each of these technologies addresses specific challenges in integrating renewable energy into the grid, showcasing the diverse approaches being developed to meet future energy demands. As these solutions evolve, they hold the promise of creating more resilient and sustainable energy systems, paving the way for a cleaner, greener future.

FAQ Section

1. What are energy storage systems (ESS)?

Energy storage systems (ESS) are technologies used to store energy for later use. They help manage energy supply and demand, integrate renewable sources, and improve grid stability.

2. Why is energy storage important for renewable energy?

Energy storage is vital for renewable energy as it ensures that surplus energy generated from sources like wind and solar can be stored and used when production is low, helping in balancing supply and demand.

3. What are the benefits of solid-state batteries over traditional lithium-ion batteries?

Solid-state batteries offer enhanced energy density, improved safety by eliminating flammable liquids, and potentially longer lifespan compared to traditional lithium-ion batteries.

4. How do flow batteries work?

Flow batteries store energy by circulating liquid electrolytes through a membrane, allowing for controlled energy discharge. They are scalable and efficient for large-scale storage needs.

5. What advantages does hydrogen offer as an energy storage solution?

Hydrogen offers zero emissions at the point of use, can store surplus renewable energy efficiently, and serves as a versatile, environmentally friendly energy carrier.