How Can I Optimize Solar Bracket Performance with Proper Maintenance and Cleaning?

Introduction

Solar power which is not less than a wonder of nature, became so popular worldwide? More solar panel installations are installed, better maintain the supporting structure, so that maintenance of solar brackets is also very important. Availed by Cosmic Power, these brackets are used to hold the solar panels firmly in one position which eventually helps them receive sunlight throughout the day. Nevertheless, the worst bit about lead-acid batteries is that they are heavily affected by environmental elements and eventually wear out fully. This article discusses the significance of regular upkeep and cleaning in improving solar bracket—leading to greater efficiency of your solar panel systems.

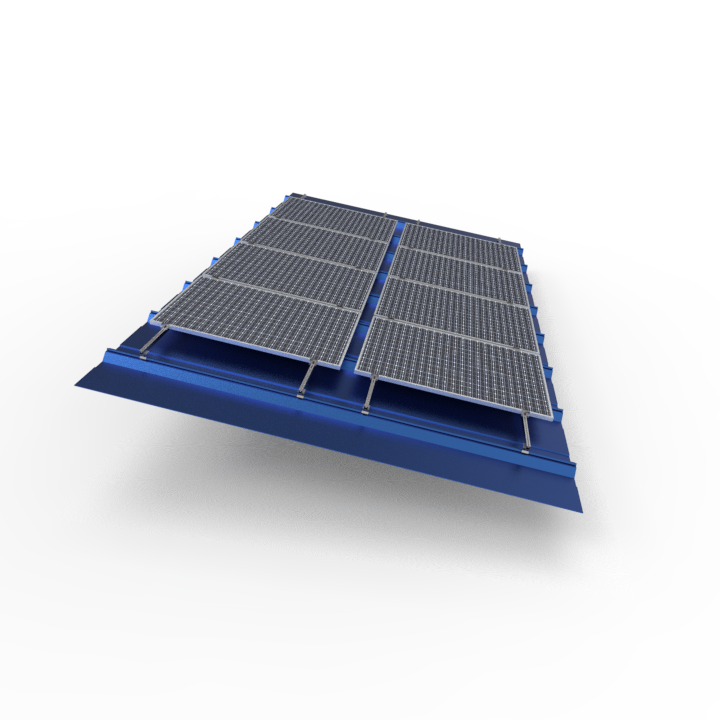

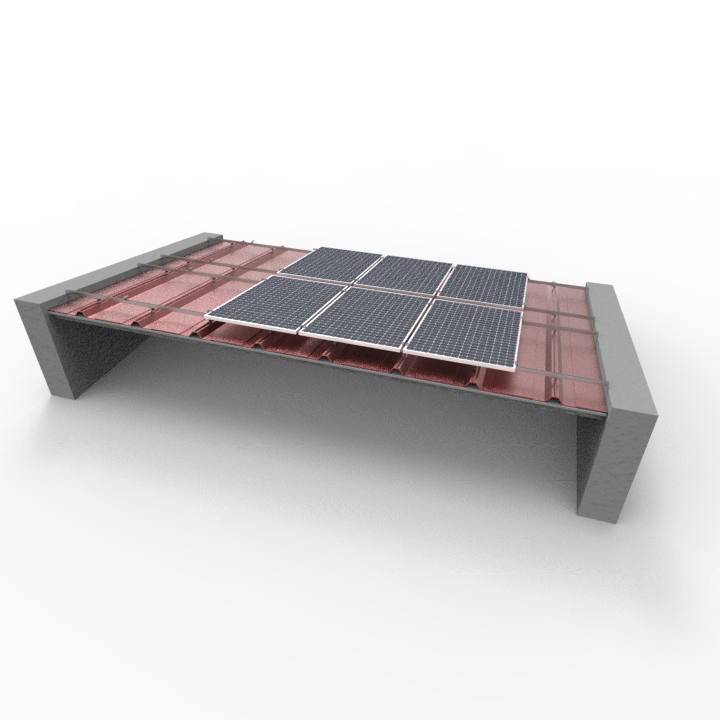

Understanding Solar Brackets

Solar brackets are truly underrated in the world of solar panel installations. Diverse types of solar panel mounts are accessible such as, roof-mounted bracket or ground mounted and pole mount each securing the panels in unique situations. These brackets are subjected to the elements and corrosion, wear crack as well so they will fail. The solar panels are therefore only as efficient and last long like the brackets which keep them in place.

Importance of Maintenance

If you are not keeping your brackets maintained they can be damaged which will, in consequence lead to failure. The support system of the solar brackets is well maintained will also affect how safe and stable your solar panels are while preformat their job, meaning this would impact its energy output. A maintenance programme should be defined according to a given environmental situation and the manufacturer's recommendations.

Maintenance Checklist

A full list of maintenance for solar brackets consists of:

Visual Inspections: Perform regular visual inspection of brackets for any sign of wear, corrosion or structural damage. Inspect for cracks and rust, or any looseness of parts that may require repair.

Tightening: Inspect all belts, bolts and nuts to make sure they are correct. These components may even loosen up with time, and because of several environmental issues like wind pressure or temperature variation.

Examine Environmental Damage: Check the brackets for environmental damages like intense winds, snow or hail. This is a key inspection in areas of extreme weather.

Cleaning Solar Brackets

Also, it is an essential part to clean solar brackets and panels. The brackets and panels may be collecting dust, dirt, and debris which will prevent sunlight. Some basic guidelines for cleaning the solar brackets and panels indicate that, one should consider using soft brushes and mild detergents so harsh chemicals do not damage the panel surface. Cleaning should be based on the environmental conditions (brackets in dusty or contaminated environments may need more frequent cleaning).

Advanced Maintenance Strategies

Maintenance techniques of solar brackets advanced

Lubrication: Regular lubricating of adjustable brackets having moving parts can help in achieving an ideal functioning as well enhancing the life span.

Corrosion resistance: Manufacturing brackets out of corrosion-resistant materials and/or coating them to withstand the elements should help minimize maintenance requirements.

Anti-reflection coatings: The application of anti-reflection (AR) coating to brackets may be used as a sunlight absorbing layer that prevents light scattering.

Troubleshooting Common Issues

Typically, Solar brackets may have the following problems:corrosion,damage,misalignment and instability. The quicker these things are noticed and addressed, the better off you will be with both efficiency of your solar panels as well as safety for them and anyone around their traditional arrays. This could include fixing or installing new brackets to help with ensuring the panels are aligned properly, and other work on panel edge alignment as well as stabilization of loose components.

Effects of Lack in Maintenance

Failing to maintain the solar brackets can decrease solar panel output, increase risk of damage and maintenance costs. In the worst cases, it can even lead to system failure and an expensive replacement. Maintenance not only makes solar brackets perform best, but also prolongs the life of the whole system component Did.

Conclusion

To maximize the stability of solar brackets and effectiveness of solar panel system, a good maintenance and cleaning are necessary. To prevent dampening of efficiency and enhance the overall life-span, keeping a certain interval like every six months schedule for maintenance work can considerably extend how long you benefit from your solar energy. Installing solar bracket maintenance protocols is a small yet critical step to help ensure the longevity of using solar energy systems.