How to choose the right size for a steel carport?

Introduction to Choosing the Right Size for a Steel Carport

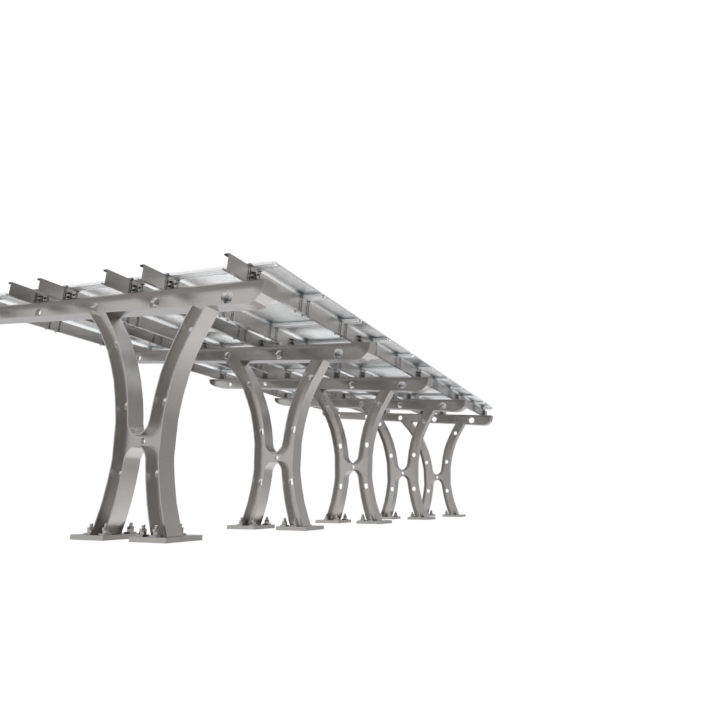

Carports play a crucial role in safeguarding vehicles from potential environmental damage and in maximizing the value of your assets. Selecting the right size is essential to adequately accommodate various types of vehicles, including cars, trucks, and recreational vehicles (RVs). A carport that is too small may not protect the vehicle effectively, while one that is too large can be unnecessarily costly. Choosing the correct size promotes the longevity and efficiency of the carport structure, potentially saving on future maintenance and replacement costs. Carefully considering these factors ensures that your investment yields long-term benefits, providing protection and convenience.

Determining Your Needs for a Steel Carport

Assessing the number of vehicles you intend to house is crucial when determining the size of your steel carport. It’s essential to calculate the minimum dimensions required by considering all types of vehicles, whether it's compact cars, trucks, or motorcycles, to ensure adequate space. For instance, a single carport is typically around 12 feet wide, suitable for one standard vehicle, while a double might range from 18 to 24 feet, ideal for housing two vehicles.

Different vehicle types demand unique spatial requirements. A truck, for example, requires more space compared to a compact car to prevent any damage and to ensure ease of access. Recreational vehicles like RVs or lifted trucks may need a taller and larger carport to provide ample clearance and protection. Ensure you account for the varying needs of each vehicle type.

Beyond vehicles, consider any additional storage requirements for tools, equipment, or supplies that you plan to keep in or near the carport. If you anticipate using the carport as a workspace, it will influence the overall dimensions and layout. Space for workbenches or storage shelves should be factored into the design, depending on your personal or business needs. Moreover, having a dedicated area for a workspace can enhance organization and functionality, ensuring that the carport serves its intended purpose efficiently.

Space and Installation Considerations for Your Steel Carport

When planning to install a steel carport, accurately measuring your available space is crucial to ensure a suitable fit and proper functionality. Begin by measuring the area with basic tools like a tape measure or wheel measure. Make sure to account for vehicle movement, such as turning radius, and paths for entry and exit. This ensures that the carport not only accommodates vehicles but also allows for smooth access.

Several factors can influence measurements, including the presence of existing structures, trees, and the ground slope. These elements can impact the positioning and installation of the carport, as they may limit space or require additional modifications, such as adjusting the carport’s dimensions to avoid obstructions. A level site is particularly important for stability, preventing future structural issues.

It's important to adhere to local zoning regulations and building codes, which dictate the carport's permissible size, height limits, and placement. Zoning laws might impose setback rules about the proximity of the carport to property lines. Failure to comply with these regulations can result in fines, removal, or alterations of your carport, leading to increased costs and delays.

Consider the foundation requirements, such as concrete slabs or footings that support the structure's durability. A solid foundation plays a critical role in the carport's longevity and resistance to weather conditions. Therefore, consulting with local building authorities or professionals is a wise step to ensure compliance and maximize the effectiveness and durability of your steel carport installation.

Choosing the Right Specifications for Your Steel Carport

Choosing the correct specifications for a steel carport is essential to meet specific needs and ensure longevity. When deciding between standard and custom sizes, it's important to understand that each offers unique benefits. Standard sizes, such as the traditional 12-foot-wide carport, are typically adequate for most passenger vehicles and offer a cost-effective solution. However, custom sizes cater to specific requirements, providing flexibility to accommodate larger vehicles or multi-vehicle storage, thus preventing the need for future alterations.

Height specifications are critical, especially when housing tall vehicles like RVs or lifted trucks. Adequate vertical space is necessary to ensure clearance and prevent damage. Similarly, width considerations are vital for accessibility. Ensure there is enough room for side-to-side maneuvering and door clearance to facilitate easy access to all areas of the carport.

Roof design plays a significant role in both the aesthetic appeal and functional performance of a carport. Options like flat, gable, and domed roofs affect water runoff and snow load, impacting the structural integrity under different weather conditions. Expert recommendations suggest materials and finishes that enhance the carport’s durability. Prioritize corrosion resistance to ensure the structure withstands various climates, protecting it from environmental wear and extending its life.

Overall, each aspect of the carport's specifications—from its dimensions to the choice of materials—should be thoroughly evaluated to match specific requirements and environmental conditions, ensuring maximum utility and durability.

Conclusion: Ensuring Long-term Functionality and Efficiency in Your Carport

Investing time in the careful planning of your steel carport can ensure its long-term functionality and efficiency. When you invest effort in selecting the appropriate sizes and specifications, it directly contributes to reducing maintenance and repair costs over time. This foresight in planning ensures that your steel carport remains a valuable asset for years to come.

Selecting the right size and specifications allows you to accommodate current needs while anticipating future requirements effectively. By considering the possibility of changes in vehicle sizes or quantity, you position yourself to adapt without the hassle of major modifications. Planning with the future in mind guards against potential inconveniences and financial burdens.

Moreover, investing in high-quality materials, such as those used in aluminum carports, enhances both the durability and performance of your structure. Quality materials not only offer robust protection against environmental elements but also ensure that the carport remains aesthetically pleasing. This investment pays off in durability and the sustained functionality of your carport.

FAQ

Why is selecting the right size for a steel carport important?

Selecting the right size ensures that your vehicles are adequately protected without incurring unnecessary costs. It also contributes to the carport's longevity and efficiency, potentially saving on maintenance and replacement costs.

What factors should be considered when determining the carport size?

Consider the number of vehicles, types of vehicles, additional storage needs, and potential workspaces. Also account for local zoning regulations, foundation needs, and available space for proper installation.

What are the benefits of choosing custom specifications for a carport?

Custom specifications allow for flexibility in accommodating larger or multiple vehicles, potentially preventing the need for future alterations. Custom sizes cater to specific spatial and accessibility needs.

How can I ensure my carport's durability?

Choose high-quality, corrosion-resistant materials and adhere to proper installation techniques. Consulting with professionals can maximize the structure's effectiveness and durability.