What are the different types of solar panel mounts available, and what are their pros and cons?

When it comes to solar panels, the way you mount them can make a huge difference. Solar panel mounts don’t just hold your panels in place—they help you get the most sunlight possible. There are different types of solar panel mounts, each designed for specific needs. Choosing the right one can boost your energy efficiency and save you money.

Fixed Mounts

What Are Fixed Mounts?

Fixed mounts are the simplest type of solar panel mount. They hold your solar panels in a stationary position, usually at a fixed angle. Once installed, they don’t move or adjust. These mounts are often set up to face the direction that gets the most sunlight throughout the year. You’ll commonly see them on rooftops or in open spaces where the angle can be optimized during installation.

Pros of Fixed Mounts

- Affordable: Fixed mounts are one of the most cost-effective options. They’re simple to design and install, which keeps costs low.

- Low Maintenance: Since they don’t have moving parts, you won’t have to worry about frequent repairs or upkeep.

- Durable: These mounts are built to last. Their sturdy design can withstand harsh weather conditions like strong winds or heavy snow.

Cons of Fixed Mounts

- Less Efficient: Because they stay in one position, they can’t follow the sun’s movement. This means they might not capture as much sunlight as other types of solar panel mounts.

- Limited Flexibility: Once installed, you can’t adjust the angle or direction. If your energy needs change, you’ll need to make significant modifications.

- Not Ideal for All Locations: Fixed mounts work best in areas with consistent sunlight. If you live in a place with varying sun angles, they might not be the most efficient choice.

Adjustable Mounts

What Are Adjustable Mounts?

Adjustable mounts give you the flexibility to change the angle of your solar panels. Unlike fixed mounts, these allow you to manually or mechanically adjust the tilt to match the sun’s position. This feature makes them a great choice if you want to maximize energy production throughout the year.

Pros of Adjustable Mounts

- Improved Efficiency: By adjusting the angle, you can capture more sunlight, especially during winter or cloudy seasons.

- Seasonal Flexibility: These mounts let you adapt to seasonal changes, ensuring your panels perform well year-round.

- Better ROI: The increased energy production can lead to higher savings on your electricity bills over time.

Cons of Adjustable Mounts

- Higher Costs: These mounts are more expensive than fixed ones due to their design and added functionality.

- More Maintenance: Moving parts mean you’ll need to check and maintain them regularly to ensure they work smoothly.

- Manual Adjustments: Some models require you to adjust the angle manually, which can be time-consuming.

Tracking Mounts

What Are Tracking Mounts?

Tracking mounts are one of the most advanced types of solar panel mounts. These mounts follow the sun’s movement throughout the day, adjusting the angle of your solar panels automatically. They use either single-axis or dual-axis systems. Single-axis tracking moves the panels horizontally, while dual-axis tracking adjusts both horizontally and vertically. This technology ensures your panels always face the sun, maximizing energy production.

Pros of Tracking Mounts

- Maximum Efficiency: These mounts capture the most sunlight possible by following the sun’s path. This can significantly boost your energy output.

- Higher Energy Savings: With increased efficiency, you’ll see a noticeable reduction in your electricity bills over time.

- Great for Large Projects: If you’re working on a big solar installation, tracking mounts can help you get the most out of your investment.

Cons of Tracking Mounts

- High Costs: These mounts are among the most expensive options due to their complex design and technology.

- Maintenance Requirements: Moving parts mean more wear and tear, so you’ll need to perform regular maintenance.

- Space Needs: Tracking mounts require plenty of room to operate effectively, which might not be ideal for smaller properties.

Rooftop Mounts

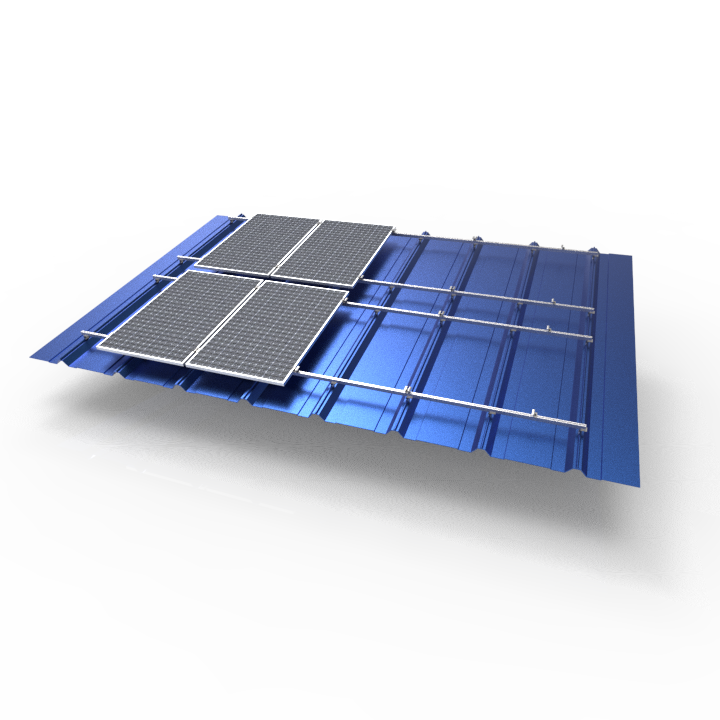

What Are Rooftop Mounts?

Rooftop mounts are one of the most common types of solar panel mounts. As the name suggests, these mounts secure solar panels directly onto your roof. They’re designed to make the most of the space you already have, which is especially useful in urban or residential areas. Rooftop mounts can be installed on various roof types, including flat, sloped, or even metal roofs.

Pros of Rooftop Mounts

- Space-Saving: You don’t need extra land or open space. Your roof becomes the perfect spot for solar panels.

- Cost-Effective Installation: Since you’re using an existing structure, you save money on additional mounting infrastructure.

- Aesthetic Appeal: Rooftop panels blend into your home’s design, making them less noticeable than ground-mounted systems.

Cons of Rooftop Mounts

- Weight Concerns: Not all roofs can handle the weight of solar panels. You may need structural reinforcements.

- Angle Limitations: The angle of your roof might not be ideal for capturing sunlight, which could reduce efficiency.

- Maintenance Challenges: Cleaning and maintaining rooftop panels can be tricky, especially on steep or high roofs.

Choosing the right solar panel mount depends on your needs. Fixed mounts are simple and affordable. Adjustable mounts offer flexibility. Tracking mounts maximize efficiency. Rooftop mounts save space... Explore the types of solar panel mounts to find your match.