What are the key considerations for ensuring the safe and secure installation of solar panel mounts?

Installing solar panels safely is essential for protecting your home and ensuring long-term efficiency. Improper installation can lead to structural damage, energy loss, or even safety hazards. You must plan carefully and follow safety protocols to avoid these risks. Paying attention to key considerations will help you achieve a secure and effective setup.

Key Considerations for Site Assessment

Evaluating Roof or Ground Conditions

Before installing solar panels, you need to assess the condition of your roof or ground area. For roof installations, check for signs of wear, such as cracks, leaks, or sagging. A roof in poor condition may not support the weight of the panels or mounting system. If you plan to install panels on the ground, ensure the area is level and stable. Uneven terrain can lead to improper alignment, reducing efficiency. You should also verify the soil's ability to hold the mounting structure securely. A thorough evaluation prevents future issues and ensures a safe installation.

Determining Optimal Sunlight Exposure

Solar panels perform best when they receive maximum sunlight. Identify the direction and angle that capture the most sunlight throughout the day. In most cases, south-facing installations provide the highest energy output. You should also consider seasonal changes in the sun's position. Use tools like solar pathfinders or online mapping software to analyze sunlight exposure. This step ensures your panels operate at peak efficiency year-round.

Key Considerations for Structural Integrity

Assessing Roof Load Capacity

Before installing solar panels, you must evaluate your roof's ability to support the added weight. Solar panels, along with their mounting systems, can be heavy. If your roof cannot handle this load, it may lead to structural damage or even collapse. Start by checking the age and condition of your roof. Older roofs may require repairs or replacement before installation. You should also consult a structural engineer or a professional installer to calculate the load capacity accurately. This step ensures your roof remains safe and stable after installation.

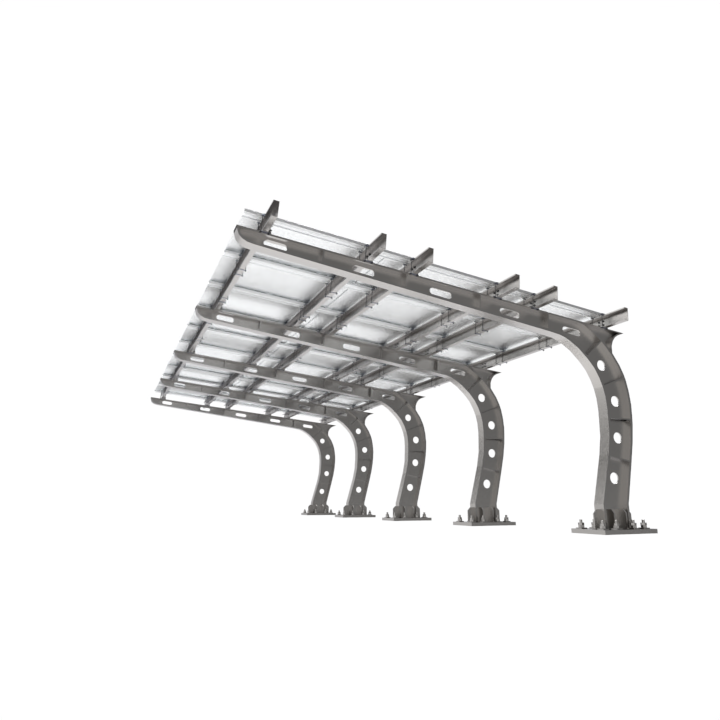

Reinforcing Weak Structures

If your roof or ground structure shows signs of weakness, reinforcing it becomes essential. Weak areas, such as sagging beams or cracked supports, can compromise the safety of your solar panel system. Reinforcement might involve adding extra support beams, replacing damaged materials, or strengthening the foundation. Addressing these issues before installation prevents costly repairs later. Always prioritize safety by ensuring the structure is strong enough to handle the weight and withstand environmental stresses.

Key Considerations for Selecting the Right Mounting System

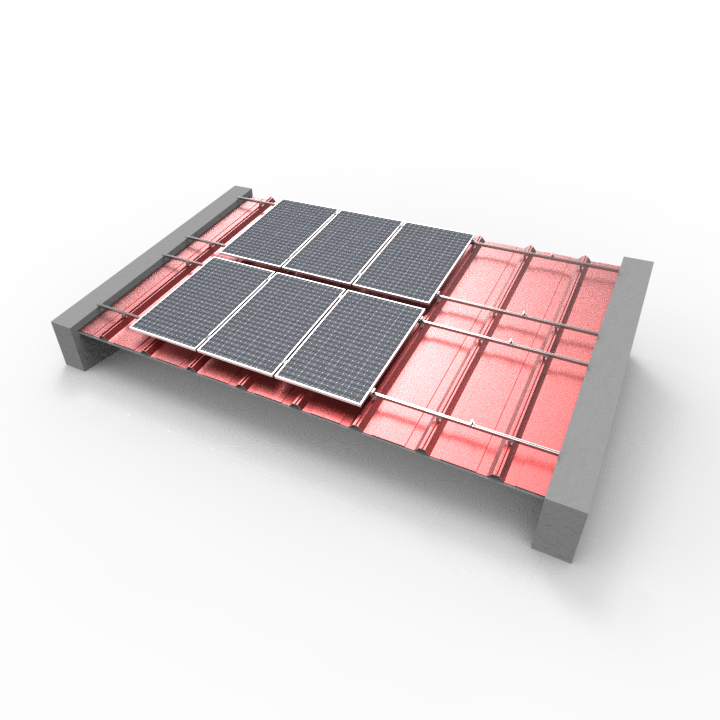

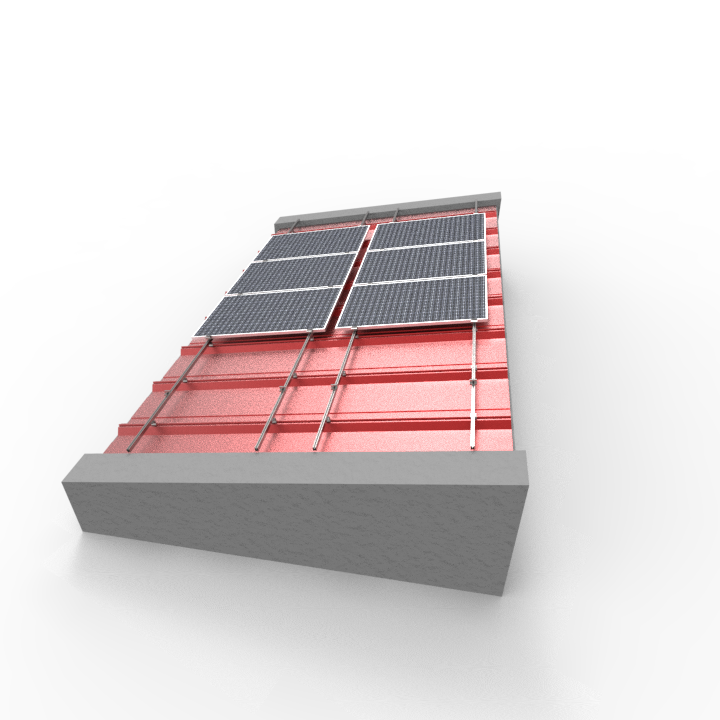

Fixed vs. Adjustable Mounts

When choosing a mounting system, you need to decide between fixed and adjustable mounts. Fixed mounts hold solar panels in a stationary position. These are ideal for areas with consistent sunlight throughout the year. They are simpler to install and require less maintenance. However, they may not capture sunlight as efficiently during seasonal changes.

Adjustable mounts allow you to change the angle or direction of your panels. This flexibility helps you maximize energy production by adapting to the sun's position. Adjustable systems work well in regions with varying sunlight conditions. Although they cost more and require additional effort to adjust, the increased efficiency can offset these drawbacks over time. Consider your location and energy goals when deciding between these options.

Material Durability and Corrosion Resistance

The materials used in your mounting system directly impact its lifespan. Look for mounts made from durable materials like stainless steel or anodized aluminum. These materials resist corrosion and withstand harsh weather conditions. Avoid cheaper options that may rust or degrade quickly. A durable mounting system ensures your solar panels remain secure and functional for years.

Key Considerations for Weatherproofing and Environmental Factors

Protecting Against Water Leaks

Water leaks can damage your roof and compromise the safety of your solar panel system. You need to ensure that the mounting system is sealed properly to prevent water from seeping through. Use waterproof flashing around the mounting points to create a tight seal. Inspect the roof for any existing leaks or weak spots before installation. Address these issues to avoid further damage. Regular maintenance checks can also help you catch and fix leaks early. Protecting against water leaks ensures your system remains safe and your roof stays intact.

Wind and Snow Load Resistance

Strong winds and heavy snow can strain your solar panels and mounting system. You must choose a mounting system designed to handle the wind speeds and snow loads in your area. Secure the panels firmly to prevent them from shifting or detaching during storms. For regions with heavy snowfall, consider installing panels at an angle that allows snow to slide off easily. Reinforcing the structure can also provide extra support. Preparing for these environmental factors helps you maintain a durable and reliable solar panel system.

Safe solar panel installation requires careful planning and attention to detail. You must evaluate site conditions, ensure structural integrity, and follow safety protocols. Compliance with regulations and proper material selection are essential. Prioritize safety at every step. If unsure, consult certified professionals to guarantee a secure and efficient setup. Your safety matters most! ?